|

|

||

|

||

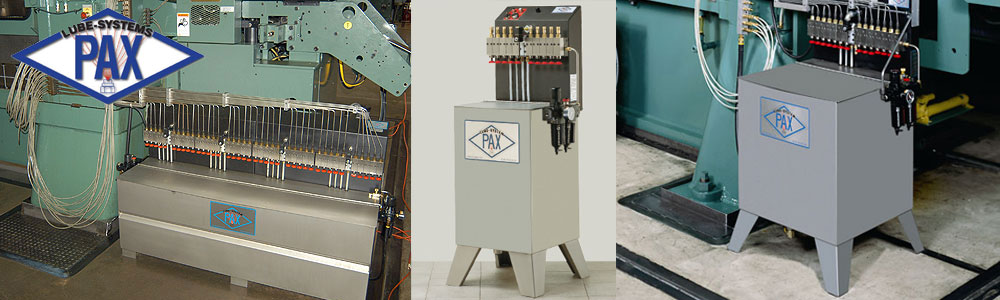

| Pax Products,Inc USA …."Designed for Stampers by Stamper "Manufacturer of Stock & Die Lubrication Systems, | ||

| Pax Products Inc. has developed an airless application system with individually adjustable lubricant dispensers/Nozzles the system will operate with controls of the press or independent of press, based on the configuration of the lube system. The system also has facility of recycling of the lubricant from the press back to the reservoir of the lube system. Since Pax Inc. has its own stamping facilities, these systems are the practical, workable solutions used to solve the problems related to stampings. |

||

The two main reasons for applying In-Die lubricant are to reduce friction and dissipate

heat. Heat can built up between the tool surface and metal, causing lubricant to break

down. This results in metal to metal contacts and galling. You need a better method

for application of In-Die Lubrication methods to improve on Tool Life and Higher

Outputs with lesser downtimes. There are many methods for applying lubricants; one of the most efficient methods of applying lubricant is the Airless Spray Techniques. The Pax Lube Systems are "pre-pressurized". The lubricant is supplied to the manifold under pressure. A constant and consistent supply of lubricant is provided. As long as there is a supply of lubricant in the reservoir, there will always be lubricant available at the distribution pumps. It also means that the distribution pumps work more efficiently because no priming is required. Benefits of using the Pax Lube System: Increased production speeds, Improved part quality, Extended Die life & Decreased Lube Consumption. |

||

|

|||||||

| Copyright © PRECILUBE INCORPORATED all rights reserved. | site designed & developed by Colour Infomedia |

||||||